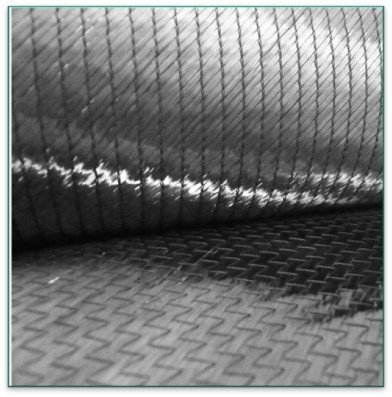

Among Selcom’s productions, a special place must be reserved for a type of multiaxial fabrics which is extremely strategic in the Resin Transfer Moulding (RTM) process, the bindered ones. In this particular process, resin is forced into a mould using high pressures in order to achieve uniform filling. In order to guarantee the stability of the intended moulds, Selcom offers its range of multiaxial bindered fabrics, to which a powder binder (usually a thermosetting resin) has been applied. Â The binder function is to guaranteed dry preforming shape geometry and to mantain reinforcement stability during the injection phase.

This is a solution particularly interesting for supercars sutomotive industry, where RTM is widely used to produce structural composite parts such as bonnets, roofs, doors, fenders, wings, etc.