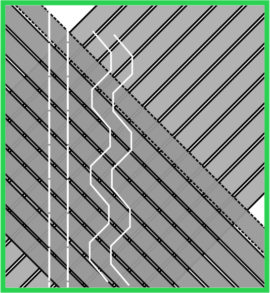

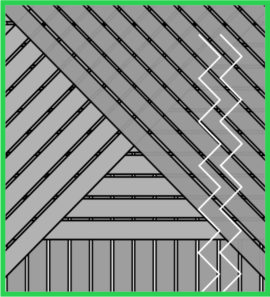

The boating industry is one of the main areas in which the multiaxial fabrics Selcom have had the most development in recent years, the company was the first also to achieve structural fabrics suitable for infusion (SCRIMP) the particular design of these fabrics allows a fast and complete impregnation of the composite low-pressure infusion (by assembling dry fabrics with polymeric composite materials). Furthermore, Selcom team use the best possible compatibility with polymeric composite materials used by our customers.

Selcom multiaxial fabrics are used for the construction of almost all the structural parts of a boat: hull (bottom and sides), deck, superstructure, internal bulkheads, reinforcements in general. As the most technologically advanced multiaxial fabrics and mechanically superior to traditional fabrics, they find their most natural use in racing boats, in the pleasure yacht, the sailing boats and motor in those engaged in the transport goods, which are major benefits, lightness and strength and consequently a reduced fuel consumption.