© 2024 Selcom Multiaxial Fabrics.

Close Menu

- Home

- Chi siamo

- Certificazioni

- Settori

- Prodotti

- Prodotti Overview

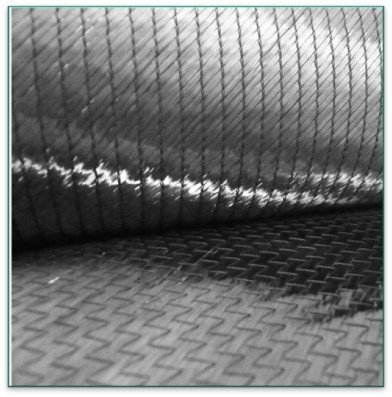

- Fibra di Carbonio – Reti bilanciate bidirezionali

- Fibra di Carbonio- Tessuti Multiassiali Biassiali

- Fibra di Carbonio – Tessuti Multiassiali Quadriassiali

- Fibra di Carbonio – Tessuti Multiassiali Triassiali

- Fibra di Carbonio – Tessuti Multiassiali Unidirezionali

- Fibra di vetro “E” Tessuti Multiassiali Triassiali

- Fibra di vetro “E” Tessuti Multiassiali Unidirezionali

- Fibra in vetro “E” – Tessuti Multiassiali Biassiali

- Fibra in vetro “E” – Tessuti Multiassiali Quadriassiali

- Woven – Nastri Unidirezionali

- Contatti

- News